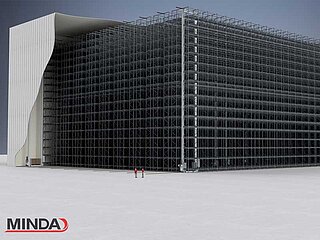

Following the successful installation of several in-house storages for raw materials, among others at Janmar Centrum in Poland, MINDA has developed to a reliable partner in the field of high-rack warehousing and is supplementing the complete range of intralogistics products for the corrugated board industry with the first large-scale project of a high-rack warehouse for finished goods.

The conceptual design of a storage system into already existing buildings is done by digital measurement of the actual condition, ensuring a high planning security and accuracy.

In the project planning phase already, Minda works out together with the customers a solution tailored to their applications. As every high-rack warehouse varies in its customer-specific framework conditions:

- Number of storage positions

- Dimensions

- Formats and weights to be stored

- Pallet types and dimensions

- Constructional and geographical conditions

- Storage and retrieval times

- Versions of the storage and retrieval machines

Realized project

An example for the individuality of customer requirements is a high-rack warehouse project where MINDA uses various storage and retrieval machines in order to meet the specific customer requirements in the best possible way.

Different formats can be flexibly stored in the high-rack warehouse using telescopic or satellite technology. This option provides the modular storage of large and small formats with the aim of an optimal utilization of storage space.

The start of production of the project with approx. 20,000 storage positions and a height of 41 m is planned for autumn 2019.

The empty pallets pass through a pallet inspection unit and are automatically stored in the high-rack warehouse and, if required, automatically fed to the loading station.

Automation

The warehouse management software system WMS 1.8, based on the established control and visualization system MoveIT, has been extended to offer the user a uniform user interface. The interfaces are thus reduced to one platform and allow the user many integration options at the same time. Storage and retrieval cycles as well as stock transfer and optimization processes based on the customer's route planning are controlled via this system.

For the implementation of such large-scale projects MINDA cooperates with established, strong partners, each contributing its own core competencies, so that the synergies for a successful project conclusion are ensured.

Training and Service

After completion of the installation and commissioning phase, MINDA offers a comprehensive after-sales service. In addition, MINDA trainers familiarize the operators with the production process. A continuous expansion of the service department enables optimal support, at first level, around the clock.

As a full-range supplier for intralogistics, MINDA has made it its business to accompany the customer as a strong partner from the first draft up to the after-sales service and to realize with him the best solution for his success.