Movement means progress

An essential component of the in-house material flow is the transport of products.

As diverse as your products, the tasks are as complex. Therefore, it is easy to get to the point where the use of standard components can no longer cope with the demands placed on them.

Demanding situations, restricted space conditions or obstacles – we will find the right solution for your specific application.

Set up, align, convey, stack, rotate, reposition, lift or distribute - palletless or on pallets - we move your products.

All components are tailored by us to your specific circumstances.

Tailor-made components which move

Roller conveyor

Roller conveyors are a frequently-used conveyance element for conveying various goods. These are exclusively piece goods. The piece weight ranges from a few hundred grams to several tonnes.

This conveyance element is very versatile for use in different production processes. From sorting, storage or distribution to commissioning and readying for despatch.

In contrast to other conveyance elements, roller conveyors are generally low cost and achieve the aim of simple piece goods conveyance reliably and without being high maintenance.

By adjusting the roll division and the roll diameter, a wide variety of products (boxes, packages, containers, plates) can be transported up to customer-specific special pallets. Furthermore, roller conveyors can be adapted very well to the spatial conditions of the usage location by adjusting the working widths, lengths and heights.

Benefits/ advantages

- Low maintenance

- Repair-friendly

- High stability

- Piece weights of up to the double digit tonnage range

- Dimensions can be adjusted

- Different sensors

- Driven/ not driven

- For heavy duty applications

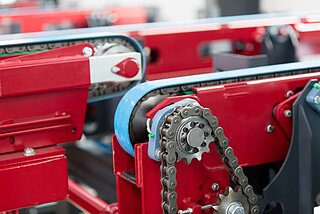

Chain conveyor

Chain conveyors are used for transporting special containers, grid boxes, pallets (cross direction), special pallets and other heavy plate-shaped products.

The conveyance chains can be configured according to the requirements of the conveyance goods. For example, the chains can be equipped with spikes. The conveyance goods are therefore held especially well on the conveyor. In addition, care belts can also be used for as gentle and mark-free conveyance.

The number of chain strands depends on the material and its load distribution. Different speeds, conveyor widths and conveyor lengths are possible.

Benefits/ advantages

- Good maintenance conditions

- High stability

- Piece weights of up to the double digit tonnage range

- Low energy requirements

- Different sensors

- Reversing possible

- Step plates - accessibility

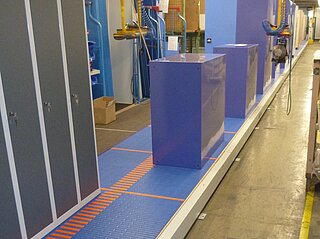

Plastic chain conveyor

Due to numerous advantages, the plastic chain conveyors have replaced the driven roller conveyors for certain transport tasks.

However, when using plastic chains, the conveyance goods have a larger support surface. This ensures a safe and smooth run for caring conveyance. The goods do not get dented and the quality of the products is maintained.

Conveyance without pallets is also possible. This avoids returning and providing empty pallets within production.

In contrast to roller conveyors, plastic chain conveyors are accessible. This enables the staff to enter and cross the conveyance surfaces without the risk of stumbling or slipping.

Benefits/ advantages

- Good maintenance conditions

- Secure and quiet run

- Jerk-free transport through frequency controlled drives

- Reversing possible

- Accessibility without risk of stumbling or slipping

- Different formats/ sizes and qualities

- Conveyor surface are easy to clean

- Quiet

- Conveyance load uo to 12 t and more

Turntable

Turntables integrate a conveyance element in their design and serve to change of direction in the conveyor line when transporting general cargo.

This conveyance element can collect from several star-shaped feeding conveyor lines and, for example, convey onwards to packaging or first hand over to star-shaped several conveyor lines.

A turntable can be used to direct conveyance in various bend angles without having to change the alignment of the conveyance goods. Furthermore, in an assembly line, turntables can turn the product in order to enable work on multiple sides of the assembly stations.

The deck of a turntable can be optionally equipped with a roller conveyor, a plastic chain conveyor, a chain conveyor or an angular transfer.

Benefits/ Advantages

- Diameter and height can be adjusted

- To be used in limited spaces

- Safe accessibility

- Reversing possible

- Adjustable loading capacity

- Any turning position

- Conveyance surfaces are easy to clean

- Variable deck design

Angular transfer

Angular transfers are used to change of direction when conveying piece goods. In contrast to curves, angular transfers save space. If the entire system is arranged strategically, you can therefore use angular transfers to save installation space and save additional elements to turn and align the piece goods.

During transfer, the corner transfer unit lifts conveyed goods from the incoming conveyor and sets it down (usually at an angle of 90 degrees) on the outgoing conveyor. In relation to the conveying direction, the transported material is rotated by 90 degrees

Depending on how the conveyance goods are configured and which support surfaces are present, angular transfers can be manufactured in different designs. Both the main conveyance element and the transverse conveyance element vary.

Benefits/ advantages

- High stability

- Good maintenance conditions

- Dimensions can be adjusted

- Adjustable loading capacity

- Solid versions possible

- Conveyance surfaces are easy to clean

- Variable deck design (roller-, chain-, plastic chain conveyor)

- Heavy duty applications

Transverse shuttle/ transfer carriage

Transfer carriages are rail-mounted trolleys that are normally unmanned and can approach several conveyor lines / production lines at a right angle to the actual conveyance direction. If it is necessary, a lift table can be integrated. Thus transfer carriages can approach conveyor lines with different working heights.

They are used to distribute pre-products to the relevant production lines or to collect the finished products from the different production lines in order to convey them to the despatch area, for example.

Transfer carriages can also be used to bridge long, straight conveyor lines without a buffer function. Depending on the requirements and the sequence, it is cheaper to procure and use one of these shuttles as of a certain path length than to convey using several conveyance elements in a row, such as roller conveyors for example.

Benefits/ advantages

- Connection to machining or conveyor lines

- Dimensions can be adjusted

- Adjustable loading capacity

- Adjustable speed

- Good maintenance conditions

- Different sensors

- Variable deck design (roller-, chain-, plastic chain conveyors)

- Height-adjustable by lift table

- Solid versions possible

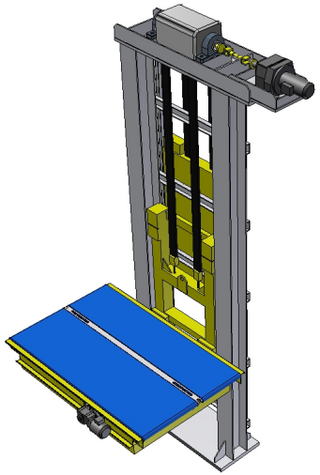

Vertical lifter

Vertical lifters open new perspectives for production and warehouse logistics. Thanks to a direct path upwards, space reserves that were not accessible previously can be made accessible.

Vertical conveyors distribute all types of piece goods reliably to different production and storage levels. Thanks to their low footprint, they are often superior and cheaper alternatives to lifts and forklifts.

Vertical conveyors are adapted to the customer’s requirements. Individual requirements with regard to the design size, load range and dynamics are included in the entire system concept.

Benefits/ advantages

- Pallet-free or palletised conveyance

- Long service life

- Maintenance-friendly

- Variable deck design

- Exact positioning

- Quiet

Stack turner

Stack turners can be integrated into conveyor lines. The relevant product is moved in between two conveyors and clamped by the stroke of a conveyor. After turning by 180°, the clamp is released and the product can move out.

It does not have to be turned back; this can be performed with the next product. This shortens the cycle time.

Depending on the design, the turning unit can be used for alignment at the same time. In this case, the clamp is less tight and turned via a limit stop on one side. Products are then aligned according to the limit stop contour.

Benefits/ advantages

- Length, width and height can be adjusted

- Load class is adjustable

- Turning longitudinally and at a right angle to the conveyance direction

- Turning with aligment

- Can be implemented without hydraulics

- Good maintenance conditions

- Solid versions possible

Further MINDA solutions for building and insulation industry

Examples for realised conveyor systems

Our services and fields: