Tailor-made and comfortable solutions for workshop equipment

The manufacture of rail vehicles and the necessary continuous maintenance and repair require a large number of machines, plants and devices.

Our ideas and solutions are as numerous as your daily problems in everyday work. With our customized product solutions we help you with your manufacturing processes and their optimization.

Features such as safety, ergonomics and economy are familiar to us. We develop and mnufacture customer-specific products, such as hydraulically folding pit covers, lifting platforms for working pits, storage and transport equipment as well as conveyor systems for the production of components and assembly groups.

Product examples for individual workshop equipment

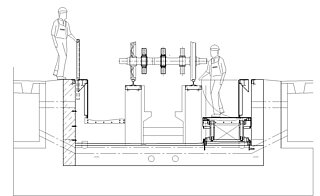

Hydraulically folding covers for lateral working pits

Lateral working pits are workstations located below the workshop level, from which assembly work as well as maintenance and repair work can be carried out on the bottom or at the side of rail-guided vehicles.

Ergonomics and safety under floor

In this customer-specific example, the lateral working pits are equipped with folding profile grid covers. The pit covers are electro-hydraulically opened and closed. The swivel mechanism, however, alo allows opening the grids, when vehicles are standing above the pit.

After opening the pit covers and locking them in 90°-position, the grids serve as fall protection.

Usability of the pit covers

In this case, the covers can be cntrolled individually. Thus, it is not only possible to work at the rail vehicle below ground level but at the same time laterally on ground level. This is also provided by the section control.

In this individual product example, each pit is divided into 3 sections, whereby one section consists of several flaps (modules). These are opened or closed after the other.

Of cource, the sections can be designed variably if required.

Monitoring of hinged covers

3 sensors per flap were used for the lifting and lowering movement. They define the end positions of the open and closed position. In addition, the end position of the electric lifting sylinders is monitored in order to ensure the locking and unlocking process.

Technical Data

Pit (Length x Width): approx. 45,900 x 3,900 mm

Covers (Length x Width): 3,810 x 1,140 mm (22x), 3,700 x 1,140 mm (1x)

Number of covers: 12 links, 11 rechts

Power per Hydraulic unit: 1.5 kW

All dimensions as well as the number of covers or hydraulic units can be individually defined in order to adjust them to customer requirements.

Benefits/ advanges

- flexible working levels

- no manual covering and uncovering required

- parallel work at the rail vehicle possible

- at the same time fall protection for the open pit

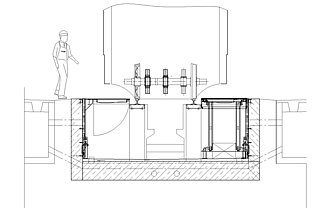

Lifting platforms for lateral working pits

Lateral working pits are workstations located below the workshop level, from which assembly work as well as maintenance and repair work can be carried out on the bottom or at the side of rail-guided vehicles.

Ergonomics and flexibility

Serveral hydraulic scissor-type lifting tables can be installed inside the lateral working pits, which can lower a long area of the platform on both sides of the rail tracks.

In this application we talk about 13 m, which are lowered to a depth of 950 mm. The middle section, with a depth of 1,600 mm, serves as accessto the pain pit, which is located between the rails. Due to different working levels, the personnel can work safely and more easily.

Lateral pit opened

In open condition, several working levels are provided. All scissor-type lifting tables on one side of the working pit are lowered to the bottom. The step-type scissors are formed into stairs and the central pit cover is folded downwards. The railing is extended.

Thus, the maintenance staff reaches an optimal viewing and workingheight to carry our inspection tasks.

Lateral working pit closed

In closed condition all scissor-type lifting tables are extended and protected by hydraulically operated bolts. The step-type scissors build a flat surface to the floor and it is possible to drive on them, but they also provide working possibilites laterally at the vehicle.

The central pit cover rests on the scissor-type lifting table and the railing is retracted.

When closed, floor conveyors can drive on stairs, safety reilings and working platforms at the level of the platforms by automatically extending safety supports.

Monitoring of delayed lifting and lowering

During the lifting and lowering processes, the lifting hight of each lifting table is determined by sensors.

Technical Data

All data can be adjusted according to customers`or application-specific requirements.

| Number of lifting tables per pit: | 4 |

| Dimensions lifting table (WxL): | 1,210 x 4,655 mm |

| Load capacity per lifting tables: | 2 t |

| Passability (in locked condition) | 1.2 t Axle load (Total load: 2.4 t) |

Benefits/ advantages

- several working levels are provided

- no manual covering and uncovering required

- parallel work at the rail vehicle possible

- ergonomic comfort

- usability of transport routes by locking possibility

Transport carriage

Transport carriages are used wherever recurring parts and components have to be moved within a plant. Mobile assistants often play an important role even for transport purposes on the outdoor premises.

The daily challenges for intralogistics can be solved with an transport carriage. Individual transport carriages are allways used when standardized carriages are not suitable: for example, to transport sensitive parts or model-specific assemblies from place to place without damage. Even parts or assemblies weighing serveral tons can be transported safely and in a stable way.

We offer you tailor-made transport carriages for the requirements of your logistics system in order to optimize your transport processes.

The transport carriages are moved by forklift trucks or other vehicles.

Benefits/ advantages

- safe transport

- strength-saving

- also for components weighing several tons

- can also be used as mounting device

- safe handling

1. Installation carriage

This installation carriage is used for transport and intrior finishing of a maximum of four underground side wall segments.

The segments are taken out of the paint shop by means of a special traverse and then they are positioned in the installation carriage. The side wall segments are then completed with panes and interior cladding.

The position of the side wall segments on the carriage exactly corresponds to the later position in the car body, so that it is possible to assemble the side walls into the car body with the traverse.

2. Transport carriage for bogies

This transport carriage is used for the in-house transport of bogies. It is approx. 8.5 m long and has load capacity of up to 20 tons.

The carriage is equipped with two lockable pivot tables. Every wheel is equipped with a fixing brake. which is operated by means of a manual crank. Gas pressure springs provide the weight relief for the two drawbars.

The load securing is ensured ba two infinitely variable brake shoes on the loading surface. They are equipped with a contour protecting the wheel tires.

3. Pre-installation and transport carriage

This pre-assembly carriage is used for the installation of high-tension and control current channels at base frames of rail vehicles.

Mounting brackets, prefabricated ducts, compressed air tanks and other components are exactly positioned on the carriage. The pre-assembly and transport carriage is then driven under the car body of the rail vehicle, where the parts can be finally assembled.

This transport carriage has a length of approx. 20 m. It has steerable and lockable axles on both sides.

Transport and storage devices

Transport and storage racks are used to store and transport parts and components in a safe and space-saving manner.

With a robust transport frame, safe and stable transport of even heavy parts and assemblies can be ensured. Space-saving storage and transport facilities enable efficient transport and economic storage.

Some of the racks also offer the possibility of stacking them safely in order to make optimumuse of the available storage capacities. Even when loaded, the devices can be moved quickly and, above all, in a strength-saving way using a forklift truck or crane.

We offer you tailor-made transport and storage facilities - depending on the type of work and the task at hand.

Benefits/ advantages

- safe transport

- strength-saving

- optimization of storage capacities

1. Transport rack for wheel discs suitable for rail transport

This rail-mounted frame is used to hold and transport up to four wheel discs.

The holders are offset on the frame and they therefore provide an easier access for painting work. The transport frame is moved on rail tracks and can be locked against rolling away by means of a parking brake.

The transport rack provides good access from all sides and can be lifted from the rail system by crane or forklift truck.

- Length x width x height: 1,770 x 1,280 x 740 mm

- Load capacity: max. 2,500 kg

2. Transport rack for drive wheelsets suitable for rail transport

The transport rack for drive wheelsets suitable for rail transport with gear resp. suspension tube roller bearings is used to carry and transport one drive wheelset.

The wheelset is positioned on the wheel discs on roller in order to allow repair and paint work.

The transport rack is moved on rail tracks and can be locked against rolling away by means of a parking brake.

- Length x width x height: 1,380 x 900 x 670 mm

- Load capacity: max. 2,000 kg

3. Stackable transport rack for whellset axles

This transport rack are used to tranport and store each two drive wheelset axles with assembled large gear wheels.

In the rack, the drive wheelset axles are safely positioned and fixed in their position.

The transport racks can stacked and transported by crane or forklift truck.

- Length x width x height: 2,400 x 1,200 x 1,000 mm

- Load capacity: max. 2,500 kg

- permissible payload: max. 2,000 kg

4. Transport and storage rack for suspension tube roller bearings and components of drive wheelsets

These racks are used to transport and store complete asembly groups of suspension tube roller bearings and the corresponding components of drive wheelsets.

The components and assembly groups are picked up and protected in horizontal direction.

The racks can be stacked and transported by crane or forklift truck.

- Length x width x height: 1,380 x 900 x 670 mm

- Load capacity: max. 2,000 kg

Further MINDA solutions for railway technology devision

Application-specific devices and systems

Our services and fields: