Hydraulic cross laminated timber presses (CLT presses)

With our cross laminated timber presses (CLT presses) series TimberPress X, we offer the ideal press technology for the production of cross laminated timber elements from cross-laminated solid wood layers. The solid wood layers can consist of joint-glued solid wood boards or loose lamellas/panels. Depending on the application, we use one of the following three series.

With the TimberPress X 100, we press joint-glued solid wood panels into CLT press blanks, whereby the main press pressure is applied vertically.

We use the TimberPress X 100pro version if joint-glued solid wood panels have already been made in the previous production step and if they also have window and/or door cut-outs.

The TimberPress X 200 has a frontal or lateral hydraulic compression function in addition to the vertical main press pressure. Thus, the longitudinal or cross layers can consist of loose lamellas/panels and the process step "joint gluing / solid wood board production" is dropped for a part of the raw material. In addition to the small space requirement, advantages of this CLT press are the lower investment and operating costs.

With the TimberPress X 300, we compress both the longitudinal and cross layers before pressing high-quality CLT boards with the vertical main press pressure. Both the longitudinal and the cross layers consist of loose lamellas/panels. The process step "joint gluing / solid wood panel production" is thus completely dropped.

All MINDA CLT presses can be designed for batch size 1, which means 100% flexibility in the production sequence. Wall or ceiling boards with minimum or maximum number of layers can be produced fully automatically and infinitely in any size (length, width and thickness).

As an option, all three series are also available as a high-speed version (HS). In the HS version, the press opening and closing as well as its feeding and unloading take place at a significantly higher speed. This enables the use of even faster PUR glues for shorter cycle times, and capacity increases of up to 30% can be achieved.

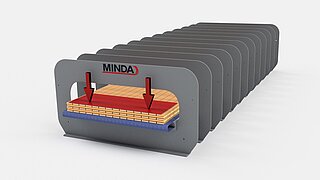

TimberPress X 100

The 100 series of TimberPress X cross-laminated timber presses has a one-dimensional, vertical main pressing pressure to press solid wood panels into CLT elements.

Max. panel length: up to 20.000 mm

Max. panel width: up to 6,000 mm

Height of press package: 300 / 400 / 600 / 1,200 mm

Automatic, infinitely variable dimension change: included

Vertical pressure: 0.6 / 0.8 / 1.2 / 2.4 N/mm²

Compression in lengthwise direction: no

Compression in crosswise direction: no

Pressure system: hydraulic

Permanent pressure control: included

Feeding / discharging: in lengthwise direction

Feeding and discharging: simultaneously

Pressing process:

In the preceding laying area, the respective press package is formed by longitudinal and cross layers previously prepared and by a suitable glue and is then transported into the press. After positioning of the press package in the pressing chamber, pressing is vertically performed by the force application of the main pressing pressure. Permanent monitoring of the pressing pressure with automatic readjustment in the event of a pressure drop is a standard feature of every TimberPress.

There are different configuration options with regard to the panel dimensions and the pressing pressure to be applied. Depending on the glue system used for each application, we offer customized solutions. By using joint-glued solid wood panels as the source material, it is also possible to produce several CLT elements in one pressing process in the TimberPress X 100 - please contact us!

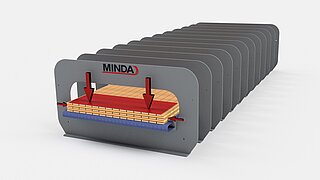

TimberPress X 200

The TimberPress X 200 series comprises all the advantages of the 100 series and adds another feature to the press concept: compression of the press package in horizontal direction!

Max. panel length: up to 20.000 mm

Max. panel width: up to 6,000 mm

Press package height: 300 / 400 / 600 / 1,200 mm

Automatic, infinitely variable dimension change: included

Vertical pressure: 0.6 / 0.8 / 1.2 / 2.4 N/mm²

Compression in lengthwise or crosswise direction: yes

Pressure system: hydraulic

Permanent pressure control: included

Feeding / discharging: in lengthwise direction

Feeding and discharging: simultaneously

Pressing process:

The production of joint-glued solid wood panels with suitable dimensions for cross-laminated timber represents a challenge - but not a problem for MINDA.

Therefore, in addition to the vertical main pressing pressure, the TimberPress X 200 has another hydraulic pressure system for compressing the press package. Installed in longitudinal or cross direction, this technology allows to close gaps in the press package in the pressing chamber, such as they may occur when using loose lamellas or several smaller solid wood panels!

This technology reduces investments in additional plant technology and saves valuable hall space. By the way: Depending on the structure of the press package, it is also possible to produce several CLT elements in one pressing process with the TimberPress X 200 - please contact us!

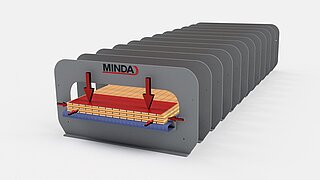

TimberPress X 300

The TimberPress X 300 is the all-rounder among the cross-laminated timber presses! Three-dimensional pressure system with vertical main pressure and horizontal compression in length- and crosswise direction for the production of CLT panels from lamellas.

Max. panel length: up to 20.000 mm

Max. panel width: up to 6,000 mm

Height of press package: 300 / 400 / 600 / 1,200 mm

Automatic, infinitely variable dimension change: included

Vertical pressure: 0.6 / 0.8 / 1.2 / 2.4 N/mm²

Compression in lengthwise direction: yes

Compression in crosswise direction: yes

Pressure system: hydraulic

Permanent pressure control: included

Feeding / discharging: in lengthwise direction

Feeding and discharging: simultaneously

Pressing process:

In addition to the main vertical pressure, this series has got two other hydraulic pressure directions. The compression of the press package in longitudinal and (!) in cross direction within the pressing chamber enables the production of cross laminated timber by using loose lamellas, both for longitudinal and cross layers.

This often leads to very compact plant layouts and usually reduces investment costs considerably. Nevertheless, full flexibility in production is maintained, because in principle the TimberPress X 300 can also press joint-glued solid wood panels into CLT elements. Our innovative transport concept for the feeding and unloading process ensures a safe infeed and outfeed of the press packages, even when using loose lamellas, while minimizing non-productive times simultaneously - please contact us!

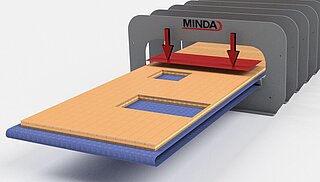

TimberPress X 100 pro

The TimberPress X 100 pro sets new standards in terms of resource efficiency! The completely revised press concept enables pressing of press packages where the subsequent window and door cut-outs have already been taken into account! This saves resources, avoids waste and increases productivity.

Max. panel length: up to 20.000 mm

Max. panel width: up to 6,000 mm

Height of press package: 300 / 400 / 600 / 1,200 mm

Automatic, infinitely variable dimension change: included

Vertical pressure: 0.6 / 0.8 / 1.2 / 2.4 N/mm²

Compression in lengthwise direction: no

Compression in crosswise direction: no

Pressure system: hydraulic

Permanent pressure control: included

Feeding / discharging: in lengthwise direction

Feeding and discharging: simultaneously

Pressing process:

After the press package has been positioned in the press chamber in length direction, the main vertical press pressure required for the cross-laminated timber production is specifically adapted to the board contour - recesses in the press package do not represent a problem. Thus CLT boards of highest quality with maximum flexibility are produced.

In case of press packages with cut-outs, no press forces can be applied in horizontal direction, so the press package must consist of joint-glued solid wood boards.

We would also be happy to offer you our solutions for the production of solid wood boards with window and door cut-outs as well as for the production steps in front and behind the press.

CLT boards with cut-outs are the king class of CLT production and MINDA is your partner in this field!